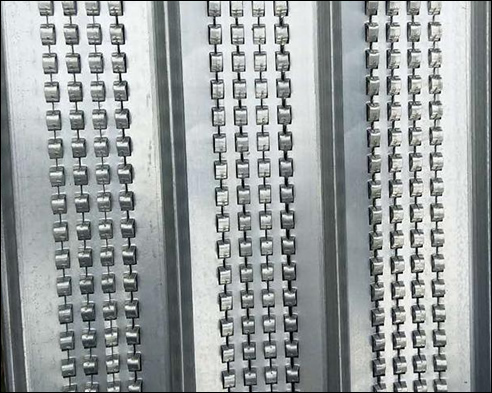

High Ribbed Lath is a metal lath with expanded hi mesh and U patterns, offering better anti-stress capability and forming flexibility than common rib lath. This product is popularly used in joint construction and various concrete formwork. Hi Rib Lath is also called High Rib Formwork Lath or simply High Rib Formwork. High Ribbed Formwork Lath forms an enhanced mechanical key for the second phase concrete pouring.

EXPORT TYPES

Hy Rib Lath Expanded Metal

Surface treatment: Hot Galvanized

Color: Silver

Feature: Corrosion Resistance

Length: 2.44 m x

Width: 0.61 m

Sizes can be customized

For bridge construction.

Hi ribbed mesh type,

0.30mm thickness, 12x8, rib height 5mm, rib distance 100mm, lath width 610mm

Hy rib type: 3.4 hy rib lath (7/8") used in concrete forming

Popular in USA market

Available in gal. steel and stainless

Hy rib formwork:

Specification: 450mm width, 2200mm length, 0.28mm thickness

Material: Galvanized mild steel

Mesh type: Hy rib expanded

Weight: 2.3kg/pc

Singapore

Hi rib mesh, hot dip galvanized

Material:

Q195/SGCC

Finish: Hot dipped zinc coating galv.

450mm x 2200mm x 0.23mm

Min. tensile strength:270N/mm2

For Indonesia

tunnel forming template

All our hi rib lath products are properly packed for sea transportation.

Common packing:

10pcs/bundle with 2 metal strapping, 5

bundles with 3 metal strapping, 90 bundles/pallet

Other packing and special packing upon request.

ASTM 653 standards,

BSEN 10327 standard,

BSEN 10088-2 type 1.4301 standard,

Other equivalent.

High Ribbed Lathe offers superior anti-stress capability, strength and forming flexibility compared with common ribbed lath.

Materials:

Galvanized steel metal sheets;

Stainless steel sheets.

Structures:

This high ribbed lath has longitudinal ribs, small inverted ribs and small herringbone meshes.

Features:

Hy ribbed structure;

Superior strength and spanning capabilities;

Excellent engineering quality and construction security;

Less formwork pressure, reduced overall support requirement;

Concrete is easier to see and monitor during pour process, hence the risk of trapped air and voids within the concrete is greatly reduced.

Fixing:

Hi rib lath is typically stapled, nailed or screwed to the substrate.

The hi ribbed expanded metal lath is widely used as permanent assembly free formwork lathing, in following construction works:

Tunnels bridges, valve basement systems, sewage systems, subways, retaining walls, nuclear power plants, shipyards;

Water pools and marine engineering works;

High rise building projects;

Irregular and bending pattern works;

Other concrete construction and reinforcements.

Design Example of Galvanised Hy Rib Lath, Model 2200x450

Product Details:

Material: Q195/SGCC

Min. tensile strength: 270N/mm2

Finish: HOT-DIP GALVANIZED

Length: 2200±3mm

Thickness: 0.28(+0.05/-0.02)

Details per design reference and sectional drawing attached

| Hy-rib Mesh Lath ( Specifications and sizes can be customized.) | |||||

| Thickness (mm) | Weight (kg) | Width (mm) | Length (mm) | Rib Height (mm) | Rib Distance (mm) |

| 0.21 | 1.70 | 450 | 2200 | 14-20 | 90 |

| 0.23 | 1.90 | 450 | 2200 | 14-20 | 90 |

| 0.30 | 2.48 | 450 | 2200 | 14-20 | 90 |

| 0.35 | 2.90 | 450 | 2200 | 14-20 | 90 |

| 0.40 | 3.30 | 450 | 2200 | 14-20 | 90 |

| 0.45 | 3.70 | 450 | 2200 | 14-20 | 90 |

| 0.50 | 4.10 | 450 | 2200 | 14-20 | 90 |